Aluminum Die Casting vs. Aluminum Gravity Casting: Which is Better?

Aluminum die casting and aluminum gravity casting are two popular methods for producing high-quality aluminum parts. These casting methods are used in a wide range of industries, including automotive, aerospace, and electronics. Both processes involve the use of molten aluminum, but they differ in the way that the metal is poured into the mold.

In aluminum die casting, molten aluminum is injected into a steel mold under high pressure. This process is ideal for producing complex parts with tight tolerances and a smooth surface finish. The resulting parts are strong, lightweight, and durable, making them ideal for use in a variety of applications. Aluminum die casting is a cost-effective way to produce large quantities of parts, making it a popular choice for manufacturers.

Aluminum gravity casting, on the other hand, involves pouring molten aluminum into a mold using gravity. This process is ideal for producing large, simple parts with a consistent wall thickness. The resulting parts are strong and durable, but may have a slightly rough surface finish. Aluminum gravity casting is a cost-effective way to produce low to medium volumes of parts, making it a popular choice for manufacturers who need to produce parts in smaller quantities.

Aluminum Die Casting

Process Overview

Aluminum die casting is a manufacturing process that involves injecting molten aluminum into a mold under high pressure. The mold is typically made of two halves, which are clamped together to form a cavity in the shape of the desired part. Once the molten aluminum is injected into the mold, it solidifies and takes on the shape of the cavity. The mold is then opened, and the part is removed.

Advantages

Aluminum die casting offers several advantages over other manufacturing processes. First, it allows for very precise and complex shapes to be produced with a high degree of accuracy and consistency. Second, it is a very efficient process, with high production rates and low material waste. Third, aluminum is a lightweight and durable material that is highly resistant to corrosion, making it ideal for a wide range of applications.

Applications

Aluminum die casting is used in a variety of industries, including automotive, aerospace, electronics, and consumer goods. Some common applications include engine blocks, transmission housings, heat sinks, and electronic enclosures. The process is particularly well-suited for parts that require high strength, tight tolerances, and complex geometries.

Overall, aluminum die casting is a versatile and efficient manufacturing process that offers many advantages over other methods. Its ability to produce complex shapes with high precision and consistency makes it an ideal choice for a wide range of applications.

Product Name | Aluminum/ Zinc/ Magnesium die casting service | |||

Material | Aluminum alloy: ADC12, A356, A380, etc. | |||

Zinc: ZA3#, ZA5#, ZA8#, etc. | ||||

Magnesium: AZ91D, AM60B, etc. | ||||

Weight | 0.015-8kg (0.033-18lb) | |||

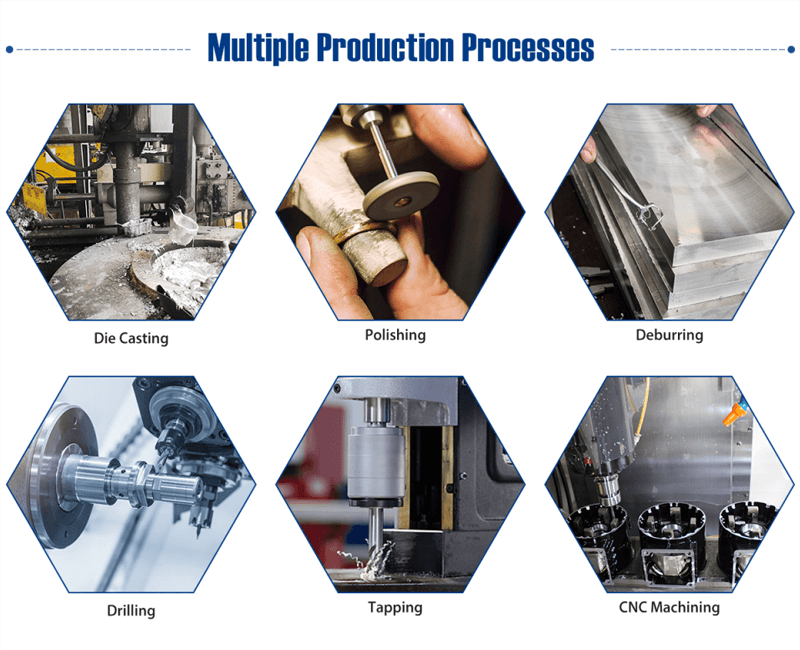

Process Name | 1 | Incoming material inspection | 8 | Cleaning |

2 | Material | 9 | Appearance inspection | |

3 | Melting | 10 | Leakage testing | |

4 | Die casting | 11 | Inspection parts after chromatin | |

5 | Deburring | 12 | Packaging | |

6 | Process inspection | 13 | Inspecting for delivery | |

7 | Machining | 14 | Delivery | |

Drawing | Provide by customer, or design according as the sample | |||

Drawing format | Pro/E, AutoCAD, Solidworks, CAXA, UG, CAD, CAM, CAE, STP, IGES, etc. | |||

Mold | Design and produce by ourself | |||

Aluminum Gravity Casting

Process Overview

Aluminum gravity casting is a popular method for producing high-quality aluminum parts with excellent dimensional accuracy and surface finish. The process involves pouring molten aluminum into a permanent mold made of steel or other materials. The mold is preheated to a specific temperature, and the molten aluminum is poured into it, filling the cavity. The mold is then cooled, and the solidified aluminum part is removed from the mold.

Advantages

Aluminum gravity casting has several advantages over other casting methods. One of the main advantages is that it produces parts with excellent dimensional accuracy and surface finish. The process also allows for the production of complex shapes and thin-walled parts that are difficult or impossible to produce with other casting methods. Aluminum gravity casting is also a cost-effective method for producing large quantities of parts.

Another advantage of aluminum gravity casting is that it produces parts with excellent mechanical properties. The process produces parts with high strength, hardness, and durability. The parts also have excellent corrosion resistance, making them ideal for use in harsh environments.

Applications

Aluminum gravity casting is used in a wide range of applications, including automotive, aerospace, and industrial applications. The process is commonly used to produce engine parts, transmission parts, and other components for the automotive industry. It is also used to produce parts for the aerospace industry, including aircraft components and engine parts.

In the industrial sector, aluminum gravity casting is used to produce a wide range of parts, including pump housings, valve bodies, and other components. The process is also used to produce parts for the medical industry, including surgical instruments and medical implants.

Overall, aluminum gravity casting is a versatile and cost-effective method for producing high-quality aluminum parts with excellent mechanical properties

Service | CNC Machining |

Sheet Metal Fabrication | |

Welding Service | |

Laser Cutting Service | |

Die Casting | |

Lost Wax Casting | |

Sand Casting | |

Stamping Parts | |

Material | *Aluminum (6061-T6, 6063, 7075-T6, 5052) etc.. |

*Steel,l(Light steel,Q235,20#, 45# ) etc.. | |

*Copper, Brass | |

*Stainless Steel (304,201,430,316,304L,316L)etc.. | |

*Plastic(ABS, Delrin, PP, PE, PC,acrylic acid)etc. | |

Finish | Transparent / color anodized;Hard anodizing;Powder coating; |

Main Equipment | CNC Machining Center(Milling), CNC Lathe, Griantry CNC Machining Center,Etc. |

Cylindrical Grinder Machine, Drilling Machine, Laser Cutting Machine,Etc. | |

Tube Laser Cutting Machine,Flame Cutting Machine,Robert Welding Arm,Etc. | |

Bending Machine, Stamping Machine,Sand Blasting Machine,Powder Coating Line | |

Die casting Machine, Precision Casting Production Line | |

Drawing Format | Step,Stp,Gis,Cad,Pdf,Dwg,Dxf Etc Or Samples. |

Delivery Time | 5-30Days Depends On the Quantities |

QC | ROSH, CE, ISO |

Tolerance | +/-0.02mm ~ +/-0.05mm |

Surface Roughness | Ra 0.6-3.2 |